There is no question that an effective oil analysis program lowers maintenance costs on rotating equipment. The trick is knowing how to run an effective oil analysis program. Companies must be proactive so the solution to an oil-related problem is not always an oil change. The real benefit of oil analysis is using the data to steer you toward solutions to eliminate oil issues. Typical internal rates of return (IRR) and net present value (NPV) over five years for a lubrication management program in a medium-sized plant are about 150 percent and $500,000. In this paper, I will provide you with best practices for using oil analysis to monitor your lubrication management program.

Getting Started with Lubrication Management

Are you waiting until you’ve implemented basic lubrication management strategies before taking those first oil samples because they might be bad? Don’t hesitate to start your program. You will likely see many problematic oil samples, but that is no reason to delay sampling. Oil-related problems are opportunities for your lubrication management program. The worse the problem is, the better the opportunity for a cost-effective solution resulting in big savings.

Start sampling before you make improvements to establish lubricant condition baselines. The initial oil analysis results provide direction of the solutions to implement.

What to Look For

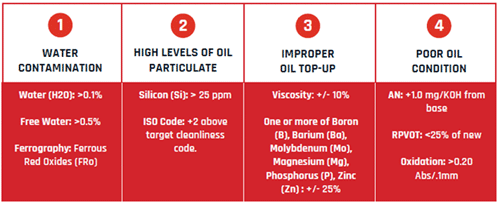

When you receive your first oil sample results, you will most likely see a number of abnormal sample reports. You may even see some critical sample reports. The main issues to watch for are water contamination, high levels of oil particulate, improper oil top-up and poor oil condition.

Figure 1. Listed above are the most common oil-related issues uncovered by oil analysis and their associated general warning limits.

Figure 1. Listed above are the most common oil-related issues uncovered by oil analysis and their associated general warning limits.

It’s possible that you will have sample reports showing abnormal or severe wear in some machines. However, the purpose of establishing a lubrication management program is to maintain proper lubrication to avoid unnecessary wear. So let’s assume your reliability team is assessing these reports and has the situation in hand. Focus on the oil-related problems.

Let’s concentrate on water and dirt for starters. Water will show up on your sample report as “water” or “H2O.” Are these results abnormal or severe? At this point, you have not set any alarm levels for water contamination. It is fine to use the laboratory defaults for your industry and type of machine. With most rotating equipment, the contamination limit for water will be 0.1 percent water. Limits range as low as 0.03 percent for turbines and as high as 0.2 percent for gearboxes. Some compressors using certain synthetic oils go as high as several percent water.

Dirt will show up on the sample report under silicon (Si) along with elemental data for wear and additives. If you are sampling machines with oil filtration, the laboratory should perform particle count testing. Ensure that you are purchasing the correct test kits for this type of machinery. Pay attention to the ISO cleanliness code as well as the particular particle counts by micron size. Abnormal or severe silicon levels and/or particle count results indicate a problem with contamination. Again, the laboratory will be using typical industry limits for silicon and oil cleanliness. This is fine when you are starting your oil analysis program. Typical silicon alarm levels for most equipment are around 25 parts per million (ppm). ISO cleanliness codes for filtered systems are typically around 19/17/14.

Improper oil top-ups are a bit more difficult to detect. Look for comments about changes in the elemental additive levels like phosphorus, zinc, magnesium, boron, barium, sulfur, etc. Monitor any changes in oil viscosity that are +/- 10 percent from the oil specification. Elemental additive levels can fluctuate as much as +/- 25 percent. A laboratory looks for other elements that shouldn’t be present or the lack of an element that should be present. Some labs have very sophisticated algorithms that not only compare the used oil to the new baseline but can determine the fluid type and compare this to the generic fluid type for the oil you have specified. They can alert you when a different type of fluid is being used. You may want to inquire whether your laboratory has the ability to perform this level of comparison.

The most blatant types of improper oil top-up or incorrect oil use is when the viscosity varies drastically from the specification. For instance, this would include when you state that you are using an ISO 320 gear oil and the oil viscosity is actually 100 centistokes (cSt). This indicates a possible top-up with hydraulic, compressor or circulating oil.

For most lubricated plant machinery, oil condition is monitored using the oil’s acid number (AN). When the oil oxidizes, it forms acidic degradation products. Increasing the AN indicates oil degradation. Once the AN is over the limit for the oil, it’s time to schedule an oil change. Large systems like turbines require more advanced testing. This includes rotating pressure vessel oxidation testing (RPVOT), water separability, rust characteristics, foaming characteristics and air release to determine if the oil is suitable for continued use.

How to Correct Problems

So the oil analysis found some problems. Now what? Realize these oil-related problems are opportunities for improvement in the lubrication management program. Most of the suggestions here are low cost and provide a high rate of return on investment. A lot of these suggestions can be implemented within a short time and don’t require a huge capital investment. So the sooner you get started, the sooner you’ll improve the bottom line on your maintenance budget.

Rated desiccant air breathers are the simplest place to start. Air breathers are an easy-to-implement, low-cost solution for preventing water and particulate from entering lubricated machinery. Air breathers reduce moisture levels when oil analysis results are showing 0.2 percent or less water contamination. Desiccant air breathers dry the air that enters the machinery during operation and also dry the headspace in reservoirs, moving moisture out of the oil. The result is drier oil. Additionally, these air breathers have a rated micron filter that cleans the air. The result is cleaner oil and better lubrication management.

For very large systems, dry gas blanketing may be an effective option. Especially when there is a readily available source of inert gas present (such as in refineries). A 1-2 PSI feed of dry nitrogen into a turbine reservoir, for instance, creates a positive pressure that prevents contaminant introduction. The dry gas causes moisture to move out of the oil and into the headspace, where it is exhausted externally.

For systems with major water contamination issues (0.5 percent or more water in the oil), a more involved lubrication management solution will be necessary. Start by ensuring that all machine hatches and inspection ports are properly sealed. Upgrading seals may also be necessary. To remove water contamination between 0.3 and 2.0 percent on smaller systems (less than 15 gallons of oil), consider using an off-line filtration cart outfitted with water adsorption filter media.

If there is too much water, you run the risk of spending a lot of money on filter elements. A bit of consultation with your filter cart provider can help you assess the situation first. If the water contamination issues are chronic (e.g., leaking cooler) and these are large systems (greater than 100 gallons), you need some serious equipment. Consider a vacuum dehydrator or bypass centrifugal filtration system. In this case, you will be investing $25,000 to $100,000.

Particulate contamination can be easily managed with proper lubrication, drain ports and off-line filtration. Purchase an off-line filtration cart that best suits your application. Hydraulic filter carts are fairly straightforward and low cost. Gearbox applications require heavy-duty equipment and ensuring the filter cart has the proper specifications for the application. The addition of lubrication and drain ports to machinery that will be part of your off-line filtration program is essential. These ports feature quick connections to allow maintenance technicians to easily hook up a filter cart and to perform oil top-ups and changes without having to remove fill and drain ports. Additionally, a rated desiccant breather can easily be affixed to the lubrication port. This further reduces particulate ingression.

Controlling improper oil top-ups can be easily managed. Start by installing proper lubrication porting on equipment to make oil top-ups easier. Provide the right kind of dispensing equipment to empower lubrication technicians to do the job properly. If you give your maintenance staff the right tools for lubrication management, they will do the job the way you intended.

Oil identification tags can be easily attached to lubrication ports. Use colors and/or symbols to identify the lubricant to be used. Dispensing equipment like dispensing jugs are available in 10 different colors to match. With some basic onsite lubrication education, your oiling crew is armed with tools and knowledge to do the job right.

If the sample report indicates poor oil condition (not contamination), you should schedule an oil change when it is convenient. If this will be an expensive oil change (more than $5,000), it may be prudent to invest in advanced oil testing to determine if an oil change is required immediately or whether the task can be put off for three months or more. Unlike contamination, in 99 percent of cases when the oil condition is a problem, you need to change the oil. If you want a better indication of what is happening with the oil, you can request Membrane Patch Colorimetry (MPC) testing for varnish potential and Linear Sweep Voltammetry (LSV or RULER) testing to determine the exact amounts of antioxidant remaining in the oil.

Monitoring Your Lubrication Management Program

Now that you’ve implemented the solutions, what should you be watching for on your oil sample reports? Once you’ve properly sealed your reservoirs from contamination, the moisture and particulate levels should start to come down. Over about six months, these levels will reach their minimum. It is worth noting the change from the baseline samples and to set reasonable targets going forward.

For instance, perhaps the gearbox water level was initially 0.15 percent and the ISO cleanliness code was 22/20/18. Six months after adding rated desiccant air breathers and an off-line filtration cart program, your moisture levels are 0.03 percent and the ISO cleanliness code is 20/18/16. You should inform your laboratory that you want to set new alarm limits on these gearboxes. Set the ISO cleanliness abnormal alarm at 22/20/18 (two codes above the new average). Also set the critical alarm at 23/21/19 (three codes above the new target). For moisture, set the abnormal alarm at 0.05 percent and the critical alarm at 0.10 percent. Now when you receive abnormal or critical sample reports (based on the water or particulate level), you’ll know what corrective action to take. Change the desiccant air breather and/or run the off-line filter cart for several days and resample.

If you implemented an oil identification and invested in appropriate dispensing equipment, you should no longer see significant additive changes (more than +/- 25 percent) or viscosity changes (more than +/- 10 percent) unless the oil condition is also suspect. When you see a dramatic change, ensure that any new maintenance staff are properly educated about preventing oil mixing. Properly train them about the use of dispensing equipment. If training is not the issue, you may have an improperly identified oil delivery and should take samples from the suspected totes or barrels.

Gauging Success

If you have been using oil analysis data to track oil-related issues in your plant, subsequent lubrication management reports should show a decreasing trend in the water, particulate and incorrect oil usage statistics.

If you have decreased the moisture and particulate levels, then you’ve increased the mean time between failures (MTBF) for those machines. In the example above, the gearbox should see an increase of approximately 1.25 times, based on the moisture reduction, and 1.25 times for the particulate reduction, which means more than a 50 percent increase in MTBF. That is significant.

Regarding oil mixing, not all incorrect oil top-ups result in lubrication issues. In several instances, serious damage can be incurred. Adding less than 1 percent of an emulsifying oil (an oil that is designed to hold water in suspension) will destroy the demulsibility of an oil formulated to separate from water (i.e., bearing circulating oil, turbine oil, etc.). Machines with bronze components should not use common extreme-pressure (EP) additives. Topping up such a machine with an EP gear oil will increase the viscosity and lead to corrosion of any bronze components long after the problem has been detected and the oil has been changed.

An investment in fluid identification, proper dispensing equipment and most importantly in training and education will drastically reduce the incidence of incorrect oil top-ups. It’s more difficult to put numbers to the savings, but any averted catastrophe warrants the improvement.

Next Steps

You’ve no doubt improved your lubrication program several orders of magnitude. Typical IRR and NPV over five years for a lubrication management program in a medium-sized plant are about 150 percent and $500,000.

The next steps involve putting in a plan for capital expenditure. Invest in a world-class lubrication room complete with an advanced oil storage system, cabinets and lubrication handling carts. Replace the off-line filter cart program with permanently mounted filtration systems on critical equipment. Augment your standard oil analysis program with an advanced oil monitoring program. Do this for critical machines and machines with large oil sumps (in excess of 250 gallons).

As you continue to improve lubricant condition, revisit and tighten up your wear, oil condition and contamination alarm levels. Your initial investment in lubrication management has likely eliminated 80 percent of your oil-related problems. The next 20 percent is going to take a lot of continual effort.

The subsequent steps involve looking for incremental improvement throughout the plant. It’s essential to continue to educate yourself on lubrication best practices. Seek opportunities for improvement to your lubrication program. Remember, world class is a moving target, so my advice is to get started now.

We previously published this article in the Reliable Plant 2016 Conference Proceedings.

By Bill Quesnel, WearCheck Canada