When I think about superheroes, I think about growing up with the television show Batman. He had some of the greatest equipment and required high reliability. I think Batman must have had a great PM strategy. He had lots of assets and good old Alfred back at the cave working on the equipment. I doubt our fictitious superhero understood the concepts of PM Optimization, but I am sure he understood the concept of high consequence failures and managing high impact failures.

Preventive Maintenance Optimization

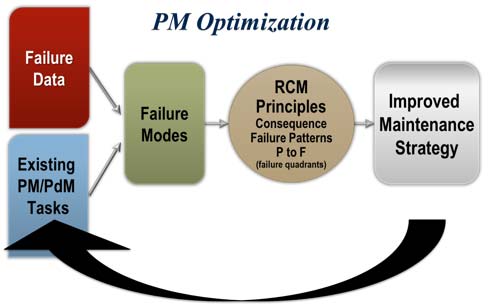

PM Optimization (PMO) is a structured process aimed at preserving and restoring the equipment condition. With PMO, we focus on identification of the failures (failure modes) and develop PM tasks to manage the failure.

Preventive Maintenance Optimization helps in fulfilling the mission of maintenance. Maintenance, or more specifically, maintain, is defined in Webster’s online dictionary (Ref: http://www.merriam-webster.com/dictionary) as:

transitive verb

1: to keep in an existing state (as of repair, efficiency, or validity): preserve from failure or decline <maintain machinery>

2: to sustain against opposition or danger: uphold and defend<maintain a position>

3: to continue or persevere in: carry on, keep up <couldn’t maintain his composure>

This is an interesting perspective since, first of all, “maintain” is a verb. It is an action aimed at “keeping in an existing state”, or to “continue or persevere in”. We find that this definition is not the definition or the mission that many shop floor maintenance personnel have. If we inquire to the floor we often find they view the mission as “fix it fast” and react to the downed equipment.

Regardless of your plant process or product, maintenance matters. In facilities, hospitals, oil fields, manufacturing sites, or data centers, asset reliability affects output. It turns out that efficient, effective, maintenance affects production (or output) and maintenance cost.

Studies validate that, to establish effective maintenance workflow, we need to focus on the key steps or “key maintenance activities”. These activities include:

Each of these steps are significantly affected by our PM and Preventive Maintenance Optimization process. Without value-added PM, we will not identify all work, we cannot prioritize properly, and we cannot affect the kitting, scheduling, execution, and analysis of the work. With value-added PM, we will not only make the maintenance work more effective and value-added, we will reduce the downtime of the equipment (for PM and for repair).

What is PM Optimization?

Preventive Maintenance Optimization is a process to improve the effectiveness and efficiency of the PM process. Effective PMs address and reduce the consequence of specific, probable failure modes. Efficient PMs are value-added tasks conducted using the least labor, downtime, and materials required to complete the task.

How can we optimize our PMs? First let’s consider the origin of many PM programs. PMs are often hastily put in place to meet a requirement or project objective. They are often cut and pasted from other machine PMs or taken directly from the OEM manual. While these might be an okay starting point, there can be a significant issue if they are left unchanged over a period of time.

PM Optimization is built upon a series of key concepts and structured processes. Some Preventive Maintenance Optimization processes are very rigid and closely follow Reliability-Centered Maintenance (RCM) process and principles, while others apply the principles of RCM, looking for application of the principles to the 20% of the problems causing the highest downtime, quality cost, or maintenance cost.

All approaches use some common elements to arrive at the most value-added PM strategy for the equipment. When optimizing PMs, we will look at failure data, PMs, experience, and functional diagrams to develop a list of probable failure modes. We will then use the concepts of failure patterns, P to F curves, consequence, and operating context to develop an improved strategy.

Using operating environment, failure patterns, and P to F, we can answer three basic questions:

- Will replacement of part on a known interval or usage reduce the probability of failure?

- Can we see it in the process of failure with sufficient time to respond?

- Is the impact of the failure high enough to warrant the cost of a PM strategy?

These three elements will help us to determine the type of PM strategy that is value-added.

In addition to developing the most value-added strategy, we can increase the standardization and quality of PM execution by developing steps and standards for PM tasks. We ask five simple questions when creating the PM task to improve the PM standard. We find that a high consequence, value-added PM should address the steps, criteria, references, and, of course, include safety information. To support this development we utilize the following five simple steps:

- What is to be done?

- How is it to be done?

- What is acceptable?

- Condition-based—what criteria or specification determines pass or fail?

- Interval-based—what criteria or equipment function must be ensured after task completion?

- What course of action should the craftsman take if the results are unacceptable?

- What do we do to ensure safety?

We will list the safety instructions first on the job plan, but we must understand what is to be done and how before we can determine the safety implications.

To summarize this information into a simple concept, it might be helpful to consider the following questions. While this might not be the most effective way to process many tasks, it does help us understand the process.

- What is the specific failure you are trying to stop (Failure Mode)?

- What is the history related to this failure?

- Is this the only task addressing this failure?

- Can you see the failure coming (P to F)?

- Can you predict when the failure is likely to occur (age)?

- How much impact would there be on Safety, Production, Cost… (Consequence) if this were to occur?

- Can you add more detail or pictures to the task to ensure higher quality of execution (What, how, criteria, what if fails)?

- How long would you feel comfortable letting this run without checking or changing (Frequency)?

- Who is the best resource to perform the task?

While you may not have a Bat Cave, you can achieve super hero type uptime and equipment reliability. Preventive Maintenance Optimization is a process that identifies probable failure modes of high consequence. It then develops strategy, steps, and standards to safely reduce the probability and impact of the failure. By using data, experience, and the passion of your employees, you can manage the high impact failure modes and reduce the high consequence failure modes to prevent the “POW!” “WHACK!” “WHAMMY!” of reactive maintenance.

This article was previously published in the Reliable Plant 2014 Conference Proceedings.

By Greg Folts, Marshall Institute